|

1936 Bugatti Atlantic Replica Project |

[06-11-12] Body half - raw part coming out of the mold

[06-11-12] Body half - rough trimmed - inside

[06-11-12] Body half - rough trimmed - outside

[06-18-12] Lying back in the molds to stabilize the shape, glueing up doorframe and door stiffener forms

[07-09-12] Rear windows frame/form and glassing up doorframe forms

[07-12-12] PHOTO OP: Doors, hatch, rear windows cut out of the (until now) monolithic body shell halves

[08-02-12] 1) Door seal lip close-up and fit check of a sample weatherstrip piece

2) Section diagram of the door push-on weatherstrip scheme [more detail]

[08-02-12] Right body half placed on foorboard to check and fine tune trim and fit

[08-02-12] Body halves pinned and being glued together at center flange -- a big step here...

The flanges, cowl to firewall lip, and rocker lap are being bonded with a single part moisture curing polyurethane adhesive.

The tee joint of the floorboards to body sides will be filleted with ~3 strips of 10 oz. cloth top & bottom.

[08-11-12] Shoulder strap attach hard-point plates...

12 ga. steel plate 24 sq. in. bonding surface should give shear strength equivalent to bolt,

webbing, and a 30G deceleration with a 225 lb. passenger (split between the three attach points).

They're curved to mate intimately to the contour of the inside of the body shells (L & R) behind the door frames.

[08-12-12] Bonded body/floorboard coming off chassis

[08-15-12] Body lying on side on floor for further glassing of bottom of floor/body tee joint,

and starting the patching of those ugly gel-coat voids & blisters...

[08-15-12] Filler neck duct forming... This is why we save stuff like old plastic buckets.

[08-29-12] Filler neck tunnel...

PVC pipe makes a good form for some fiberglass clamshells.

One half trimmed and in place...

both halves assembled -- will enclose fuel filler neck, pipe, vent, ground wire

[10-01-12] Rear hatch fit-up & latch... (interlocking nylon shoes detail)

[10-01-12] Rear hatch latch detail

[10-01-12] Cowl vent scupper pattern

[10-10-12] Scuppers - trimmed, cowl vent cut-outs, scuppers fitted, clamped & glued in place

[11-10-12] Cowl vent hinges

[11-10-12] Cowl vent control linkage parts (left)...

Ugh!... so much labor; so little relevance.

[11-10-12] Cowl vent control (left) assembled on instrument panel bracket

[11-10-12] Cowl vent control & mahogany knob

[11-13-12] This instrument panel, with the donor S10 instrument cluster, is considered a version 1.

It's intended to facilitate (when the time comes) plugging in the S10 electrical harness to as much

original connectors, sensors, instruments, etc. as possible to assure that everything is working as

on the donor vehicle before fitting more "Atlantic looking" instruments in a version 2 panel.

[11-13-12] Turned aluminum "Atlantic style" fuel filler cap glued to S10 cap with a bezel & the S10 filler neck

[03-18-13] Side window templates and hinge detail development

[04-08-13] Window templates ready to go to Tri-City Glass, Appleton, WI

[04-08-13] Door hinges - Masonite, PVC pipe, & hot melt glue check models, and cut steel parts ready for welding up

[04-27-13] Door hinges, with long straight rod to assure axis alignment while fitting up...

Hinges will be taken to The Chrome Shop in Menasha, WI.

[04-30-13] Bonding in the windshield wiper arm bushings

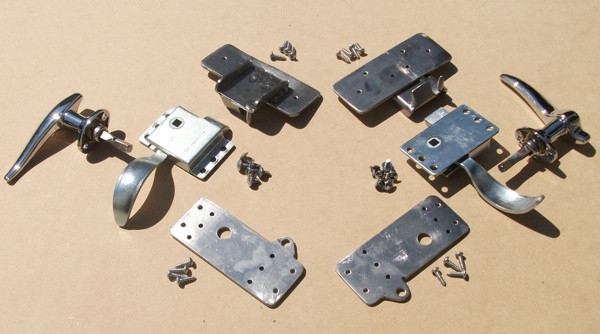

[05-08-13] Fabricated door latch mounts & striker plates...

The "universal door latches" and exterior chrome handles are from Speedway Motors.

The exterior handles are intended for something like a '32 Ford, with square vertical door edges.

The Atlantic's front door edges are swept at about 45°, so we needed to re-index

the square shaft by that much so the handle is not drooping at an odd angle.

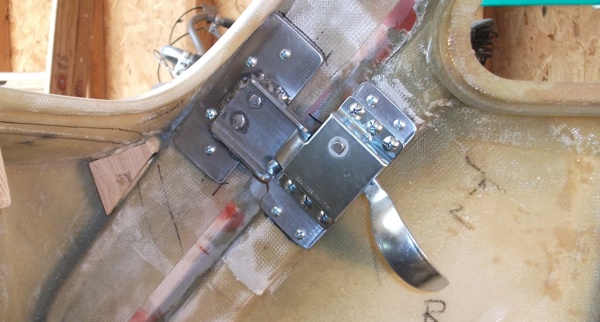

[05-08-13] Door latches, plates, & strikers fit-up

[05-08-13] Exterior door handles fit-up

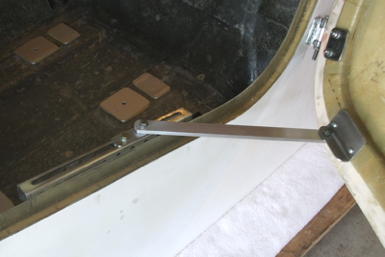

[05-16-13] Door snubbers... slider & link fit-up

[06-09-14] Rear fender layup start - white gelcoat, layer of 1.5 oz. (per sq. ft.) mat

[06-11-14] Rear fender layup - 1st layer of 10 oz. (per sq. yd.) cloth

[06-19-14] Rear fenders, inboard, raw, popped out of the molds

[06-20-14] Rear fenders, outboard, raw, popped out of the molds

[06-24-14] Rear fenders - inboard, outboard being bonded with PL polyurethane...

(The inboard fender halves bolted to the body by themselves before the clamping up and bonding was a missed photo opportunity.)

[06-28-14] Rear fenders - adding inner stiffeners...

The grey "half-tube" is polyethylene foam pipe insulation from the hardware store plumbing section, cut in two lengthwise.

It's cheap, light, flexible, can be cut with scissors and glued in place with a few dabs of hot-melt glue.

Note that the foam "half-tube" is not the stiffener itself, but is an easy to work shape-form onto which

we can lay a few layers of resin and fiberglass cloth to make the actual (hollow) stiffener section.

[07-03-14] Rear fenders - trimmed, inner stiffeners in place with four layers of 10 oz. cloth

[07-10-14] Rear fenders - black polypropylene liner / stone shield / brace...

0.187” black polypropylene plate from Onlinemetals.com .

[07-10-14] Rear fenders - drilled, filled, sanded, w/ tail light mount holes, assembled on body (until paint time)...

Fit-up is excellent!

Knowledgeable viewers may notice here that the "beetle tail" is a little flatter and wider than a correct Atlantic

shape. This was accepted to accomodate the width of the S10 donor frame at the rear leaf spring shackles.

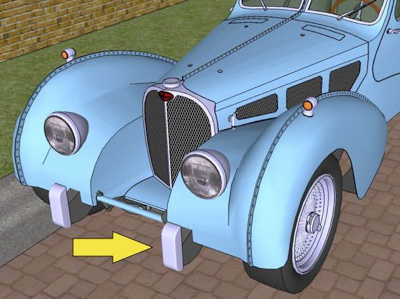

[10-29-14] Front bumperettes blanked out of 3 x 2 x 11 ga. (.120) A513 rectangular steel tube

[10-29-14] No, this is not correct for an Atlantic, but is our chosen work-around

for the donor S10 frame rails protruding forward of the front fender wings.

We'll make the frame rails look like they belong there with some little chrome bumperettes.

[11-04-14] Bumperette blanks slit & vee'd for bending and welding

[11-06-14] Bumperettes with the front faces formed to a radius (big vice, big hammer)...

The clamps are just pulling in the springback for tack welding.

[11-08-14] Bumperettes - partially (sides) welded

[11-09-14] Bumperettes - welded and ground

[11-20-14] Bumperettes - with mounting tabs, sanded and smoothed some more;

ready to take up to The Chrome Shop in Menasha, WI

[01-19-15] Bumperettes - back from The Chrome Shop ... Oooooooo! Bling!

[07-03-15] Front fenders layup start -- gelcoat, and layer of mat going on (inboard)...

[07-12-15] Front fenders layup start -- gelcoat, layer of mat, and some layers of cloth going on (outboard)

[07-21-15] Left inboard front fender (white) coming out of mold (orange)

[07-21-15] Left inboard front fender - raw, out of mold

[07-21-15] Front fender parts - rough trimmed

[07-26-15] Front fenders - fitting, trimming

[08-10-15] Front fender headlight hole layout...

Note the popcorn bowl form for the glass headlight pocket pieces.

[08-11-15] Front fender headlight holes cut out

[08-13-15] Headlight pockets getting glassed in place...

The aluminum plate bonded to the fender is attach point for a brace to the frame.

[08-13-15] Front fender headlight trial fit (left side needs some adjusting)...

The reproduction '34 Ford 9.25" dia. headlights from Speedwaymotors.com have a good correct look for an Atlantic.

[08-20-15] Left headlight mount leveling with some complementary beveled washers

[08-25-15] Bonded fender side brace attach point, and adding some outer fender panel stiffeners

[09-12-15] Clamping & bonding the front fender halves together

[09-15-15] Sanding on the front fenders -- Ooooo -- good photo op...

This is finally starting to look serious.

[10-14-15] Front "apron" to finish off between the front fenders

[10-14-15] Front "apron" in place... Not quite correct for an Atlantic; but this, along with the truncated

radiator shell is our chosen work-around to accommodate the S10 frame front cross member.

[10-20-15] Black polypropylene front fender splash shield...

0.187” polypropylene plate is from Onlinemetals.com .

[10-20-15] Front splash shield screws to the hoizontal fender brace bar; and an aluminum bonded tab at top (not visible).

| -- Site Navigation -- [Website Disclaimer] (pop-up) [Site Map / Search] | ||||

|---|---|---|---|---|

| 57SC Home | Donor/Chassis | Wheels/Tires | Body Patterns | Body Molds |

| Body Pieces | Hood/Radiator | Systems/Wiring | Interior Details | Glass/Finishing |